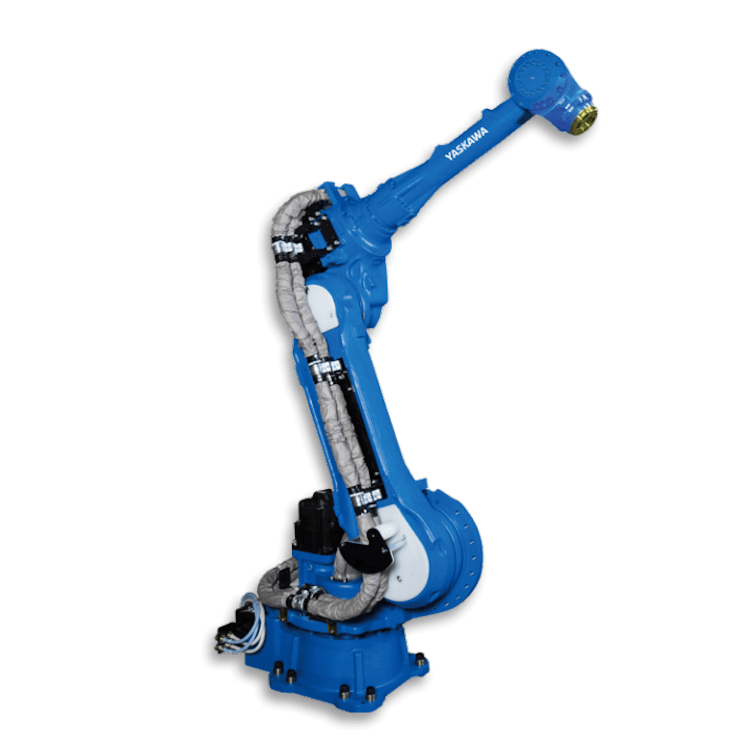

Powerful acceleration capabilities, fast axis speeds, and exceptional mounting flexibility equip the six-axis GP88 robot for superior performance in a wide variety of applications. While high wrist ratings increase handling capacity, high moment and inertia ratings enable the transfer of larger objects and heavier payloads. A reduced interference design makes high-density robot placement possible, and a wide wrist motion range reduces interference for improved application flexibility. Designed for simple installation, easy operation, and minimal maintenance, the GP88 is the ideal robot for dispensing, material cutting, material handling, Press Tending, and more.

The MOTOMAN GP88 is a versatile high-speed 6-axis robot, providing a high payload of up to 88 kg. It offers superior performance in material handling, machine tending, processing, and dispensing applications. Despite its slim body, the MOTOMAN GP88 features a wide work envelop with a small interference radius. Thereby it can be placed close to machines for loading and unloading of parts, which reduces the required floor space to a minimum. Our industry-leading, Motoman industrial robots include high-payload, high-speed, extended-reach, ultra-maneuverable seven-axis, and unique 15-axis dual-arm robots. With cutting-edge controllers, vision systems, peripherals, and other best-in-class components, we can configure a solution tailored for your manufacturing needs.

Quick Robot Wins for Greater OEE

With market demands more pressing than ever, the “throughput struggle” is real. To increase productivity and strive for 100% effectiveness, many manufacturers are placing greater focus on Overall Equipment Effectiveness (OEE) to measure the efficiency of individual machines, automated work cells, production lines, and even entire factories.

Robot Programming for Today’s Workforce

Second, to robot cost, the top concern for many manufacturers branching into robotics is the ease of programming. To address this and to unlock additional potential for a wider user group, robot suppliers like Yaskawa are constantly seeking to provide easy-to-use automation solutions that can tackle tough challenges.

Easy and Efficient Robot Control for Secondary Packaging Operations

High-performance robots optimized for packaging are delivering exceptional speed and precision for picking, packing, and palletizing applications. Whether a manufacturer’s focus is food and beverage, pharmaceuticals, consumer products, or specialty items, a growing number of advanced technologies are making it easier to configure, program, and integrate ideal solutions that meet production goals.

• Increase productivity with the powerful and efficient GP88 robot.

• Flexible six-axis robot offers superior performance for a variety of applications.

• Exceptionally fast axis speeds and acceleration capabilities reduce cycle time and increase production output.

• 88 kg payload supports a wide variety of tooling and sensors to fulfill diverse application needs.

• Reduced interference design allows close proximity placement of robots for high-density workcells.

• Wide wrist motion range eliminates interference and improves application flexibility.

• High moment and inertia ratings allow handling of larger and heavier payloads.

• Cable installation tube facilitates Fieldbus routing through the S-axis.

• Single power and control cable reduces wiring time and increases work efficiency.

• Modular robot harness design for improved diagnostics and maintenance.

• Home position data can be saved without a battery connection for easy maintenance.

• The GP88 has an IP67-rated wrist and an IP54 body standard. An XP (eXtra Protection) package that increases the body protection rating to IP65 is available.

• The GP88 can be floor-, wall-, tilt-or ceiling-mounted. Brakes on all axes.

• Compact YRC controller utilizes the lightweight standard teach pendant with intuitive programming.

| Axes | Maximun motion range(°) | Maximum speed

( °/ sec) |

Allowable

Moment(N•m) |

Allowable

moment of inertia(kg•m2) |

| S | ±180 | 170 | – | – |

| L | +155/-90 | 140 | – | – |

| U | +90/-80 | 160 | – | – |

| R | ±360 | 230 | 408 | 30 |

| B | ±125 | 230 | 408 | 30 |

| T | ±360 | 350 | 206 | 11 |

| Item | Unit | GP88 |

| Controlled axes | 6 | |

| Maximum payload | kg | 88 |

| Repeatability | mm | 0.03 |

| Temperature | °C | 0 to +45 |

| Humidity | % | 20 – 80 |

| Weight | kg | 630 |

| Power supply, average | kVA | 4.0 |

Applications: Dispensing, Machine Tending, Material Cutting, Material Handling, Press Tending

After-Sales Service: Online Services and Video technical